REQUEST FOR PROPOSAL (RFP) by 4th of September 2025.

The Challenge

Humanitarian operations, including those led by the World Food Programme (WFP), generate significant amounts of waste during last-mile delivery. In countries with limited recycling infrastructure, much of this waste — especially non-recyclable plastic packaging — is either openly burned or dumped, leading to severe environmental and health risks.

A 2021 study by USAID and WFP found that nine major humanitarian organizations sent over 68,000 metric tons of packaging waste to recipient countries, including 5,000 tons of non-recyclable metallized sachets. In low-infrastructure areas like Uganda and Kenya, plastic waste management remains a critical issue: only 30% of plastic waste in Uganda and 36% in Kenya is properly managed. Without sustainable alternatives, these practices contribute to pollution, health hazards, and long-term environmental damage.

Introduction

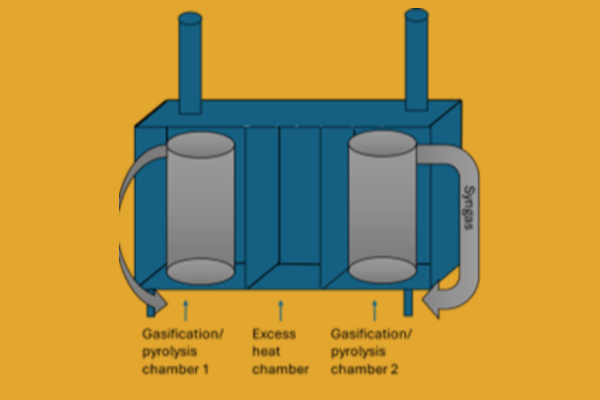

PREW (Pyrolysis Reducing Emissions from Waste) is a collaborative initiative led by Engineers Without Borders Norway, in partnership with World Food Programme, Strømme Foundation and Human Brights. The project aims to reduce plastic pollution and the harmful emissions caused by burning unrecyclable waste in rural, low-resource areas — while exploring productive uses of the heat generated in the process. Our vision is to produce simple, transportable, non-electric pyrolysis and combustion units for remote environments — a solution tailored for both humanitarian response and long-term development. We are looking for partners to help us fulfil this vision as far as feasible.

We are looking for private sector partners to, in close collaboration with Human Brights, co-develop and build two pyrolysis combustion units with income generating waste-to-x/waste-to-Energy systems (the “X-factor”). These units will be deployed for on-site testing before project end. Should the units be successful, we hope these partnerships can be extended for the further development and production and sale of numerous more units. These are the three main technical areas of development for the project:

The primary goals of the project include:

- Co-develop and manufacture two pyrolysis and combustion units, building on the insights and lessons learned by Human Brights from their testing of two previous prototypes.

- Explore and implement productive uses of an X-factor, adapted to local needs and opportunities.

- Identify and implement sustainable and locally feasible ignition/start-up methods for the pyrolysis and combustion cycle, minimizing dependence on external fuels.

The units will be integrated into local waste management systems and should demonstrate simple and safe operating conditions. Produce income-generating products supporting an economically sustainable business model in the local community. We are now looking for partners with a solid understanding of the challenge and solution we are aiming to develop. We invite eligible and interested private companies to respond to this call for requests for proposals in the innovation process by 4th of September 2025.

Below you will find the RFP, important related project documents and more information about Humanitarian Innovation Programme:

Documents:

REQUEST FOR PROPOSAL-PREW-EWB-N

EWB-N - PREW presentation

Human_Brights_PyroOnepager

Meeting Summary PREW MD

PREW Innovation Norway 2024 Projectplan and Framework

PREW -Needs assessment - Report Kenya_WFP

PREW Needs Assessment - Report Uganda _Stromme Foundation

https://hip.innovationnorway.com/

We are seeking partners with the following qualities:

- Strong technical knowledge and expertise

- Proven experience in system design and machine production

- An understanding of the local context and community needs

- Demonstrated flexibility, collaborative spirit, and an innovative mindset

|

For question and clarification: Deadline 26.06.2025 Engineers Without Borders Norway (EWB-Norway) Official/Contact Person:

Proposal submission Deadline 04.09.2025 Engineers Without Borders Norway (EWB-Norway)

|

Nima Nemati Saeid Marianne Nilsen Sturmair |

Looking Ahead

We look forward to collaborating with the selected partners from September 2025 to October 2026 in this pilot project, which will be implemented in a refugee camp in Kenya and a rural community in Uganda. This initiative presents a unique opportunity to play a central role in shaping a scalable solution that reduces emissions, improves health outcomes, and contributes to more sustainable humanitarian operations globally.

Questions and Answers:

Q1: What has been done so far in terms of development?

A1: We have tested two prototypes, and the results have been promising.

Q2: What are the key design principles for the pyrolysis process?

A2: The process should target non-recyclable plastic waste, and be adapted to an environment with limited infrastructure. The unit needs to be robust, made from components and materials locally accessible, can be maintained and repaired with tools and processes locally accessible, it must be transportable meaning modularity is a great advantage, all the while being safe to operate.

Q3: What can the heat generated from the pyrolysis process be used for?

A3: The heat can be used for:

- Water purification

- Heating air for drying materials

- Heating a medium or driving a turbine to generate electricity

- Other uses catering to the needs found in the conducted needs assessments

This "X-factor" is where we believe the business case lies which is critical for long term sustainability. The goal is for the system to manage waste independently without relying on someone’s operating budget.

Q4: What challenge exists with starting the pyrolysis process?

A4: In its current design, the unit needs to be heated up to a certain point before it starts producing gas. This initial phase requires a considerable amount of energy to push the contents over the pyrolysis threshold. After that, based on our tests, the system sustains itself using its own output.

Q5: What should the external fuel source be, and what considerations are involved?

A5: The external fuel source is needed during the startup phase, and the type of fuel is yet to be determined. It should be based on local feasibility, availability, efficiency, cost, environmental friendliness, livelihoods etc. Key questions include:

- What local fuels are available?

- What can be sourced sustainably?

- Can byproducts from the pyrolysis process be used as fuel?

Q6: What are the phases of development for this system?

A6: Please see the technical delivery and activities described in the RFP “Background information and evaluation criteria”.

Q7: Will there be a formal project kickoff or separate planning workshop with the successful partner?

A7: After a partnership has been established there will be a joint kick off/project planning workshop. Preferably physical and location pending on the partner but most likely in Nairobi. We advice to plan for that in the budget submitted.

Q8: What happens if the engineering partner is able to build the two units earlier than planned?

A8: 01.09.2026 is the latest completion date required by the donor. However, we are free to finalize the project earlier, that is not a problem and would only leave more time for testing and implementation.

Q9: For the successful partner, what travel mode/arrangements will be used to travel to Dadaab camp; considering the high insecurity cases in that part of Kenya?

A9: WFP will be in charge of travel arrangements from Nairobi to Dadaab (by WFP plane) and responsible for security for the travel and stay in Dadaab. Travel costs are still to be covered by the partner and we’d suggest to add a travel & workshop lumpsum in the budge.

Q10: Is there any preference around how we package our financials/budget, especially with regard to Design & Building the Gasifier unit? Fixed Pricing? Time & Material pricing?

A10: Fixed pricing is preferred, please make sure to define the scope and activities included in the budget.

Q11: If successful for this RFP, what are the specific timelines around a) Project kickoff b) Funds disbursements c) Site visit etc.

A11: In September the partnership will be established and contract signed. Once a partner is selected we’d together plan for a project kickoff/workshop and site visit. In other words there is not a fixed timeline for this but definitely preferable to get started as soon as possible, during Q4 2025 but of course pending availability. For funds disbursement the normal terms are 30 days upon delivery. However, as this is a co-development project, it is feasible to agree on several payments upon completion of phases specified in a project plan. We’re aware it may be difficult for a small company to advance funds, and funds disbursement can be jointly discussed with the successful partner in order to find an arrangement/installments that works for all.

Q12: Is there written documentation of the learnings and experiences from Human Brights from the first two prototypes? For examples: Data on emissions, Yield of products, temperature data from the batch runs, logging of smoke incidence, quantity of wood fuel used to get pyrolysis to exothermic phase (self-sustaining). The proposal clearly states the objective to co-develop the reactor together with Human Brights. Can we get access to the prototype drawings so that our proposal may take into consideration what has already been done?

A12: Some of the details in the requested information are unfortunately not openly available. This will be made available to the successful applicant(s). Remember: The unit- and process design is intended to be finalized as part of the project moving forward, not in the proposal phase.

Emissions: showed significant reduction in harmful local emissions compared to open pit burning. Yield: The tested units were only the pyrolysis part, of which no products are made – nor intended to be made. We are only concerned about yield with regards to the Waste-to-X solution. We logged temperatures up to 900 deg C in the insulating chamber. Ambient temperatures were close to room temperature and a heated pocket adjacent to the insulating chamber got up to 500 deg C.

Starting fuel: Unfortunately, amount of wood used to initiate the reaction was not closely logged.

It is intentional not to provide details about the previous prototypes. We want applicants to contemplate the stated function of the unit and find their own ways to complete the same task (i.e. pyrolize unwanted waste fractions with a self-sustaining process and exploit the heat). There should be sufficient information in the documentation provided by EWB- Norway along with the RFP.

Q12: How far can we deviate from the design of the first two prototypes if we deem it necessary?

A12: The applicant is free to deviate as much as necessary so long as the proposed solution is based on the core principles of the process stated in the RFP: Pyrolyze waste with the intent of reducing harmful local emissions while exploiting the heat produced for productive local purposes as discussed in the respective needs assessments.

Q13: Can a small budget be made available to produce a prototype to demonstrate and test concepts proposed, before final two units are delivered

A13: Yes, as long as it is included in your proposed budget.

Q14: In the needs assessment for Uganda p.8-9 it mentions using polythene as a starter fuel and combusting it. Do you mean to combust the polythene under the pyrolysis reactor, or is it included inside?

A14: In previous test runs we have used PE for initiation under controlled conditions and with the correct safety equipment. This is not ideal due to the harmful emissions and is not a sustainable practice for continuous operations. We are aiming to avoid the use of PE directly to initiate and concentrate on pyrolyzing it within the reactor.

Q15: In the needs assessment for Uganda p.9 it mentions the need for pre-processing of plastics such as shredding, to reduce bulkiness and reduce transport costs. This implies the use of electricity which the proposal document has asked to not design for. Is the project open to using electricity where it makes sense to do so assuming a supply of electricity can be sourced? E.g. solar battery operated, or generator driven by pyrolysis diesel.

A15: Our aim is to avoid the use of electrical power in the operation of the unit. Should, however, the use of power be necessary for the unit’s basic function, it will have to be considered. Yes, the assessment mentions shredding as a possible way of pre-processing. We will not know to which degree pre-processing will be necessary as there are too many variables at this stage in the design process. Pre-processing is not amongst the activities we are asking for in the RFP, but if the applicant finds it essential to present in their proposal, they may of course do so.